In ogni operazione di fabbricazione, la riforma e l'ispezione sono una fonte importante di tempo e denaro sprecato.che aumenta i costi di manodopera e il tempo di produzioneQuindi, una macchina può aiutarvi a ridurre il tempo di rielaborazione e ispezione?

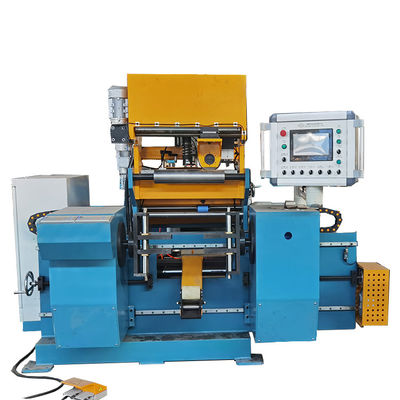

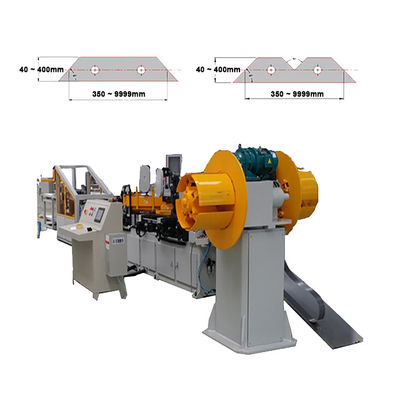

La nostra macchina di avvolgimento di pellicola a trasformatore è una soluzione affidabile che può aiutarvi a ridurre il tempo di rielaborazione e di ispezione e aumentare la vostra redditività.

Precisione della prima parte: la precisione delle nostre macchine garantisce che la prima bobina che produci sia accurata, eliminando la necessità di rilavorazioni e risparmiando un notevole tempo.

Qualità costante: la ripetibilità delle nostre macchine garantisce che ogni bobina sia realizzata secondo le stesse specifiche, riducendo così la necessità di controlli frequenti.

Monitoraggio in tempo reale: la macchina è dotata di monitoraggio in tempo reale in grado di rilevare eventuali problemi durante il processo di avvolgimento, impedendo la produzione di bobine difettose.

Manodopera ridotta: riducendo la necessità di rilavorazioni e ispezioni, si può riassegnare il personale a compiti più produttivi, riducendo così i costi di manodopera e aumentando la redditività.

Scegliendo una macchina di avvolgimento di fogli di plastica a trasformatore, non si migliora solo l'efficienza; si semplifica anche l'intero flusso di lavoro per una massima redditività.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!